|

|

Ozone gas-water hybrid technology and

product introduction

Introduction of ozone gas and water mixing device

High ozone oxidation treatment effect of the main factors in

addition to the nature of pollutants, concentration, ozone dosage,

pH, temperature, reaction time, the gaseous O3 dosing method is also

very important. O3 dosing is usually mixed reactor. Mixing reactor

(contact reactor) role has two; ① promote gas, water diffusion

mixing; ② so that gas, water full contact, rapid response; ③

increase ozone gas in water residence time; mixing reactor design to

consider when ozone the water molecules in the diffusion rate and

the reaction rate and pollutant. When the diffusion rate is large,

and the reaction rate of the ozone step speed control process, the

mixed structure of the contactor should be sufficient to facilitate

the reaction. Pollutants in this category alkyl sulfonate, tar,

CODcr, BOD5, sludge, ammonia, etc., the reactor can be microporous

diffuser plate bubble column. When the reaction rate is large, the

diffusion rate for the entire ozonation process speed control steps,

structure type should be conducive to ozone accelerated

proliferation. Fall into this category of pollutants of iron (II),

Mn (II), cyanide, phenol, hydrophilic dyes, bacteria, etc.,

generally water treatment can be used as a reactor injector, the

effect is more ideal.

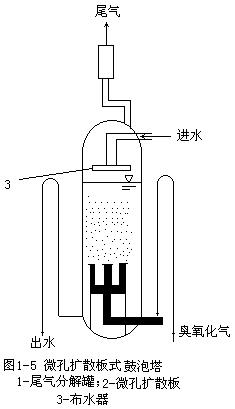

Microporous diffuser plate bubble column shown in Figure 1-5.

Ozone gas from the bottom of the microporous diffuser plate

(diameter of about 15 ~ 20um) ejected countercurrent contact with

the waste; tower can be filled with ceramic ring, plastic ring

packing, in order to improve water vapor exposure conditions. The

device is characterized by a long time can maintain a certain

concentration of ozone is conducive to ozone and water pollutants

adequate response. In addition, the device has a large liquid

volume, volume adjustment easy.

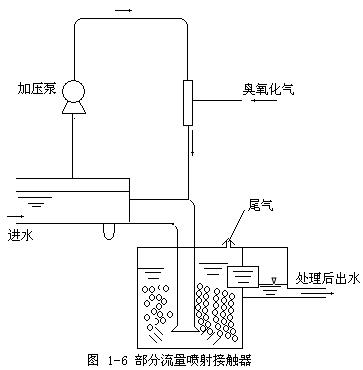

Partial flow jet contactor shown in Figure 1-6. High-pressure water

through the ejector and the ozone gas inhaled water, this device is

characterized by a well mixed, but the contact time is shorter.

Recently, there was a static mixer (Figure 1-7). Also called static

mixer tube mixer, a pipe installed in a number of propeller blades,

propeller blade has the adjacent two opposite directions, the flow

dividing the rotary motion generated by contact with the ozone many

tiny vortices. The water gas are fully mixed. The ability to mass

mixer, ozone utilization of up to 87% (73% pore diffusion), and less

energy-consuming equipment, low cost, high performance I produced

mixed results while incorporating aeration Hybrid integrated mixing

and jet apparatus has added a static mixing device (see product

navigation - gas-water mixing device) greatly enhance the

disinfection of drinking water in the gas-water mixing efficiency.

Since ozone gas is generated by high-energy method, ozone exposure

is also very important economic benefits. Contact system appropriate

cost - benefit assessment should seriously consider are:

(1) The actual amount of dissolved ozone;

(2) contact the solute and (or) the efficiency of the reaction

suspension;

(3) contact or diffusion means of the energy needed for the

operation;

(4) different contacts each specific maintenance tasks:

(5) Operation processing charges.

For a higher degree of mixing

or shear sufficient to produce the interface area, can use the

mixing tank, a static mixing apparatus, and an axial mixer (pipe

mixer) associated with.

Representative equipment:

BNP-YWS type high concentration ozone water disinfection equipment

Using a gas filter, high

concentration of oxygen gas source, ozone generator, static mixing

device and a dynamic mixing and integration integration technology.

BNP-YWS type high

concentration ozone water disinfection equipment Main technical

characteristics:

● Ozone concentrations up to

1mg / L, 2mg / L, 3mg / L, 4mg / L-10ppm, can replace chemical

fungicides and UV sterilization.

● The PSA oxygen gas source,

so high concentrations of ozone, avoiding the use of air source of

nitrogen oxides into the drinking water treatment applications

generated when the nitride may affect water taste, using oxygen gas

source comparison equipment water taste sweet.

● generation of corona

discharge cell gap, high efficiency, small size, high-frequency

characteristics of a good, stable, high concentrations of ozone

produced. Ozone absorption apparatus specially designed for

real-time residual ozone gas decomposition, solve the workspace

ozone pollution problems.

● source of oxygen - ozone -

Treatment synthetic design, air and water mixed with imported

advanced gas-liquid mixing pump Southern (vortex impeller mixer),

good mixing effect. The machine then water electrical connection can

be used, without external devices, easy to operate.

● Low noise, mobility, the use

of convenient operation, good working environment. Control panel

friendly design, simple operation, and convenient.

Note: This equipment is generally applicable to high concentration

ozone water disinfection 1-2T / h of water, a higher amount of water

used for mixing tower form my company to help customers configure

different options of high concentration ozone water full set of

equipment.

Print |

Print |  Close

Close

|