|

|

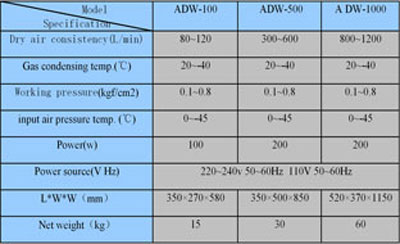

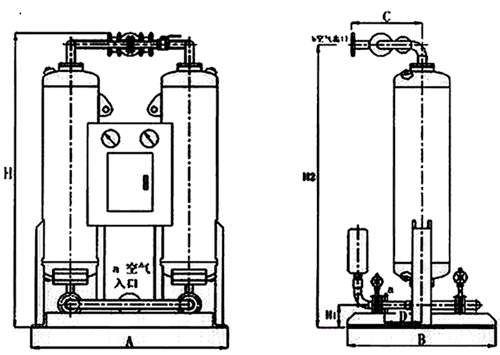

ADW series no heat regenerating PSA air dryer

Ⅰ、Working Principle:

Based on the principle of transforming and

adsorbing, regenerating and recycling,the apyrexia

regenative transforming and adsorbing drier make the

desiccant to adsorb by using the self-heat from the

pressure of the system then disengage its adsorption

by switch to the atmospheric pressure and elicit

10—15% of desiccate gas to regenerate the desiccant

from the exist of the drier once more. The

alternation of air compression

flow through two adsorbing tower, when one of the

adsorbing tower is in the condition of high

pressure, the desiccant will absorb plenty of water,

and the other adsorbing tower will indraught the

desiccated low pressure gas from the regenerated

windpipe so as to parse the water from the desiccant

absorbed then supplied the gas point with the

desiccated compress air.

Ⅱ、 Main Characteristic

1. Logical simple design ensures the contacting

time of the compress air and the desiccant bed, and

satisfies the demand of the finished gas.

2. The 30% of the desiccant is used to compensate

the natural aging of the desiccant, so as to ensure

the life-span of the desiccant can be extended.

3. The diffusing equipment has been designed

uniquely, it ensure the airflow flow to the

desiccant layer equably, avoiding from converging.

4. Unique design of the rotor, conserving 95% of

the adsorbing heat, which is used to raise the

regenerative temperature of the regenerated stage,

and then the adsorbing ability of the equipment can

be enhanced so as to regenerate downright.

5. Desiccation and regeneration adopt reversing

convection, the best effects comes out when the wet

air go through the dried adsorbing sorbent.

6. Logical size of the rotor makes the speed and

the time of the air in groove when passing the

desiccant layer and it also exert the capability of

the desiccant.

7. The system was set logically, before the air

flow to the rotor, it had been gotten rid of by the

high efficiency degreasing, then the oil and the

contamination can be dealt with immediately.

So the desiccant layer will not be polluted.

8. The design of time switching is so logically

that the export pressure can be ensure to be

stable and not fluctuate.

Ⅲ、Technique and connection:

|